Our Partner, Clandesting / Produktworks Design, & NEUVATEK’s team of seasoned industrial designers, mechanical engineers and materials

scientists deploy their knowledge in crafting our clients’ products in smart, ergonomic and eco-friendly ways. From initial

concept development to prototyping and mass production, our team is to support our clients in their endeavor to develop a

final product that exceeds expectations. Our team’s main focus is design simplicity, solution elegance, and ease of

operation for truly unique product differentiation.

Our multi-talented designers bring unique skill sets and creative vision to every project. We excel in designing

simple products that solve difficult problems. We work seamlessly with engineering teams to find the shortest and most efficient path to a solution.

Clandesting, though a solid collaborative partnership with NEUVATEK, joins our team of engineers,

designers and subject matter experts to further our superior innovation and technology value to our client community.

Jointly based in Austin, Clandestine and NEUVATEK aim to further our impact through a seamless integration of innovative design and superior technology.

Clandestine is an award-winning product development consultancy located in Austin, TX and Singapore.

Founded in 2008, we provide high-value creative services related to technology product development.

We operate on the simple premise that great design and engineering is a collaborative effort.

Our multi-talented and multi-disciplinary team has the experience to tackle even the toughest product

challenges and we work to ensure that our clients get the very best solutions possible.

Clandestine Design is a creative agency that seamlessly blurs the lines between design and engineering. We specialize in developing technology products. If you’re looking for a transparent, reliable partner to take your product from concept to market, we’re a great fit!

Support our client to transform and incarnate premature ideas into concrete road map that takes it from the virtual world toward the store shelves. During this phase a major focus covers the product identity, what will be, whom will use it and what features will charaterize it. Everything under the most simple and user-friendly intuitive possible design.

This continuous process live across the entire product design cycle and involve several parties under the management of the industrial design team. An indepth research set the main and sub guidelines for the entire design process while covering several aspects of the development such as the User Experience, User Interface, Physics, Chiemestry, Microbiology, Electronics and Firmware development.

Designers and engineers empower their accumulated skills and remove all possible boundaries prohibiting the creation of the future product and the future technology. The product design phase is considered as the core in the product development cycle. Here where ingenuity and creativity meets to incarnate the ideas into living product. During this phase,We specialize in high value and high level design and engineering services. We provide design and engineering solutions, advanced conceptual development and product architecture.

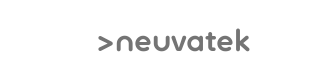

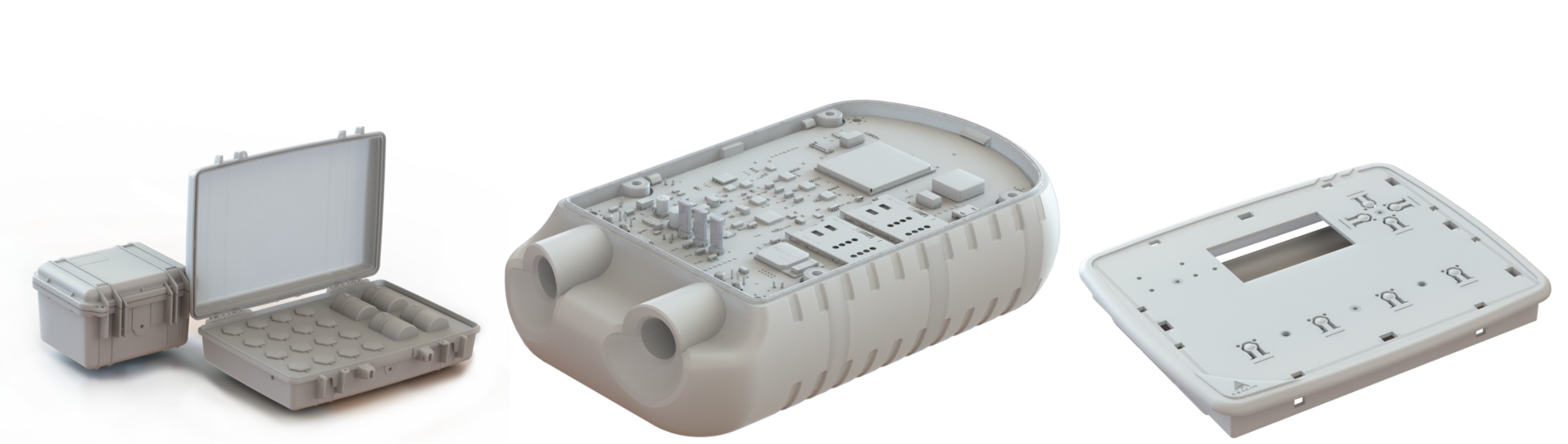

During this delicate phase, our engineers to overcome several challenges set by the the product design, user experience electronics and operation. The mechanical design transform the product form the virtual reality to the reality taking into consideration the manufacturing process, the required tooling and eventually could define a new manufacturing method.

This to cover the manufacturing details, the material, the process, the electro-mechanical compatibility, the radio frequency interference, the compliance to standard. A special emphasis on the cost structure, material sourcing, technology sourcing with several iteration to meet the client and project requirement.

During this phase our team develop internally the detailed computer added design and the computer added manufacturing wiht the required bill of materials and bill of quantities. The design is based on the latest state of the art 3D software to sculpt and transform the virtual design into a set of manufacturing directives and database.

Our team support int he prototype production covering the shell, the mechanical system and the electronics. An almost exact replication for the final product will be made through several iteration to meet the required feel and functionality.

A series of testings, internal and external, cover the product use, the functionality and the ease if use with a close loop feedback aiming to shape the product int the required frame. This covers the alfa and beta prototypes with a detailed reporting.

During this phase, our team will devleop the develop the detailed design for manufacturing, support in the cost optimization and provided if required the complete service of turnkey production through our local and overseas contract manufacturers while covering the molds manufacturing, casting, CNC Machining, anodization, injection molding, rubber overmolding, electronics manufacturing, programming, assembly, testing, certification and packaging.